Marmi Rossi is always looking for new technologies for the industrial production of marble and granite.

In this regard, we have contacted the company Pedrini from Bergamo several times, since they maintain a worldwide leading position in the manufacturing of machines and systems for the processing of natural stone such as marble and granite.

As part of the industry project 4.0, we have decided in recent years to make major investments and to purchase new machines for cutting and polishing natural stone, so we can ensure better quality when processing the slabs from our warehouse.

Constantly new machines at Marmi Rossi

The multiwire saws

These three new multiwire saws are in operation: Pedrini Multiwire Jupiter GS230 GF72, GS230 GF80 and GS240 GF80.

Respectively equipped with 72 or 80 diamond wires, this multi wire can cut the block in a single working day and produce slabs with thicknesses between 2 and 10 cm, while the wires move at a speed of 20 ÷ 35 m/s.

The flywheel rotates the diamond wires, which move vertically along the two columns to cut the block accurately into slabs.

The diamond wires are tensioned by the combined action of the machine’s rigid structure and a hydraulic pressure system.

The multiwire saw Pedrini Multiwire Jupiter GS240 GF80

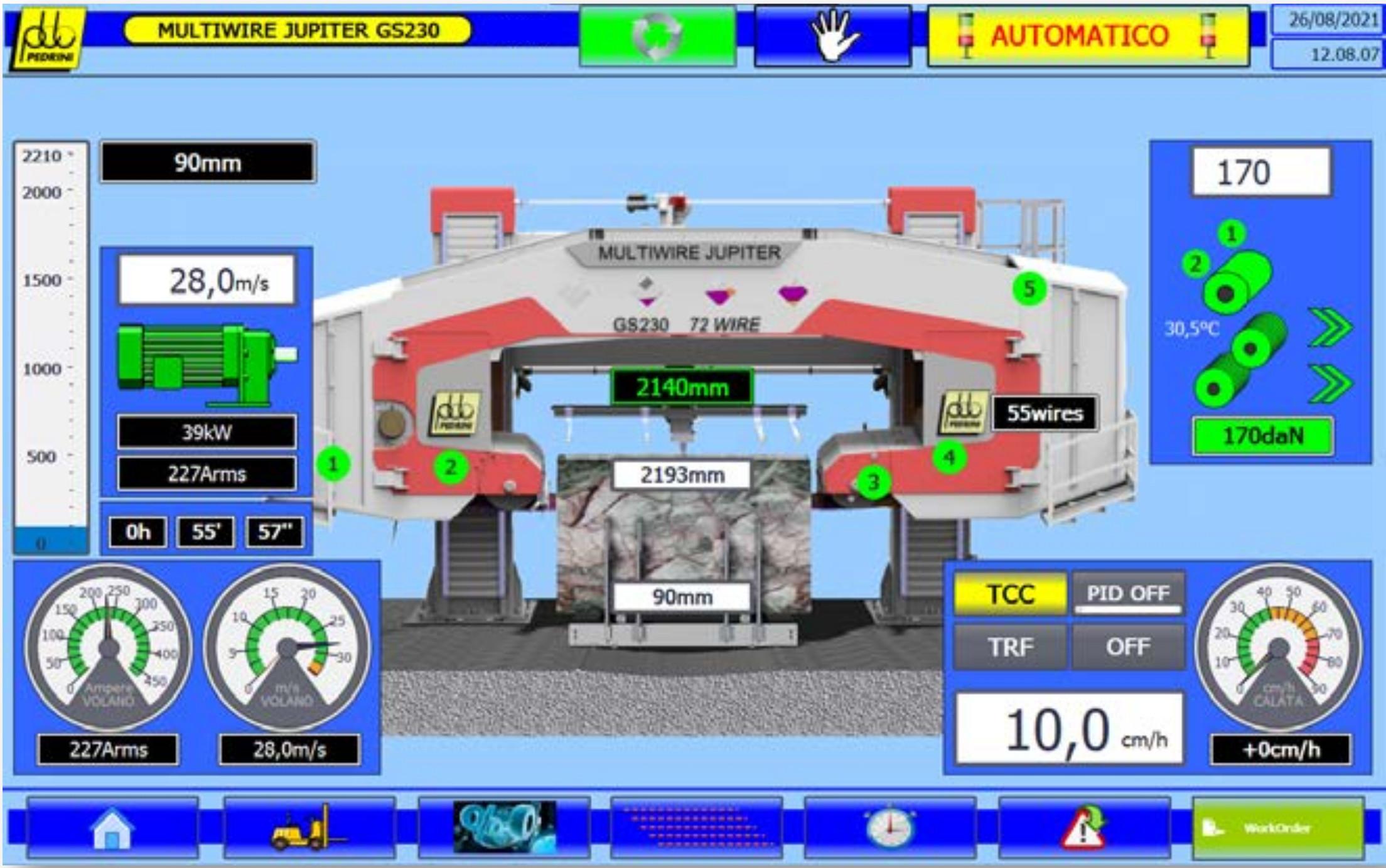

After the technicians have correctly positioned the block on the carrier trolley under the frame, the automatic cutting cycles are programmed via monitor, which features a ‘user-friendly’ interface and can also be controlled by remote.

User interface of the multiwire saw Pedrini

The polishing machine

The ‘oldest’ polishing machine in our production facility has been replaced in 2022 by the more powerful Pedrini Galaxy B220GX, which guarantees high quality polishing.

Thanks to its strength, reliability and flexibility, the new machine achieves maximum precision during the process of polishing all types of granite and quartzite, whereby even slabs with a thin thickness of 10 mm remain intact.

The polishing heads are equipped with abrasives, whose granulation becomes increasingly finer as the processed material moves from the machine entry to the output, guaranteeing maximum machining precision as well as the integrity of the slab.

The Galaxy B220GX, new addition to our highly modern machinery, is positioned next to the calibration machine and the Galaxy B220GB with 22 heads, which was also installed by Pedrini in 2018 and is still running at full capacity.

The polishing machine Galaxy B220GX

In 2025, we added a polishing machine with three independent moving carriers, the Galaxy B220 GX-T3. The new machines optimize the whole polishing process and enable us to respond to customer requests with maximum efficiency.

The resin line

As part of innovative projects that our company has been carrying out for many years, we have decided to invest, in addition to the machines from Pedrini, in two more new machines to guarantee our customers the best finished product.

The resin line Prometec with separate statistic bearings is part of this innovation: a 20 metres long machine, which was custom made to fit in the large company warehouse.

The resin line Prometec

This machine consists of two autonomous silos, one for the drying process and the other for the catalysis.

Thanks to the thermal unit, the efficient distribution of air in both silos allows the uniform drying of the material and ensures the correct resin catalysing.

In addition, the resin line ensures constant quality in processing, thanks to the highly modern construction materials, while keeping consumption low for our company.

The milling machine

Another recently acquired machine is the Donatoni D625 milling machine with 5 interpolated axes.

The compact and solid machine can perform precise shapes and orthogonal cuts up to 200 mm thickness in different directions and shapes (oblique, circular, elliptical, oblique, milled, drilled and straight, concave, convex, arched, or elliptical shaped).

The milling machine Donatoni D625

The milling machine is quick to program and guarantees products with exact dimensions.

The simple and intuitive software is controlled by an external monitor and makes it possible to optimally cut different pieces from the slab.

What does it mean to invest in industry 4.0?

For several years we’ve been investing in state-of-the-art machines and quality products that guarantee precise processing of marble and granite slabs.

The digitalization of our company to industry 4.0 has enabled us to network the entire production process.

The new system 4.0 can be accessed remotely via computer, smartphone, and tablet. Thus, we are able to program the production activity of natural stone, sending instructions and commands directly to the cutting, polishing and resin coating machines, as well as storing and analysing all the data collected by the machines during the processing stage.

The introduction of this technology has automated communication between office and production: in this way, constant monitoring of the production and work process is guaranteed.

Thanks to this implementation, our office receives useful information on the efficiency of the machines and production in real time.

This investment ensures a high production standard and quality improvement of the processed stone slabs.