In our previous articles we’ve already talked about how marble and granite had been formed by nature, now we’d like to explain how natural stone is processed and the important role of Marmi Rossi in the manufacturing process.

Our company in Cavaion Veronese processes the blocks, that come from quarries all over the world, into slabs and semi-finished products, before they are being put out on the market.

SELECTION OF RAW MATERIAL (BLOCK SELECTION)

We personally choose all the blocks in various quarries and therefore, we travel to all corners of the globe during the entire year, always in search of new material. Mostly, we visit quarries in Brazil, India, Scandinavia, Spain and Africa.

The block selection is a very important part of our job and it takes a lot of expertise and care. It is essential to recognize fractures, infiltrations and mineral inclusions inside the block, otherwise one runs the risk to obtain fragile, stained or ‘defective‘ slabs after the cutting. Obviously, each natural stone has its own characteristic and each block requires to be valued according to different criteria.

To obtain the best quality, our blocks are accurately selected, furthermore, we purchase different sized blocks of each material to guarantee our customers a large range of shapes and dimensions.

WAREHOUSE/DEPOSIT OF RAW MATERIAL

Only 2 - 3 months after the purchase, the blocks arrive at our company in Cavaion Veronese, Italy, where they are stored in the company’s stockyard.

In our block storage you can find about 500 blocks of random material types, which are stored on our stockyard according to their origin and colour. When necessary, the blocks are carried to the factory where they are cut into slabs.

Our goal has always been to offer our customers a large block storage with an excellent choice of material and the certainty of a rapid delivery.

BLOCK SAWING

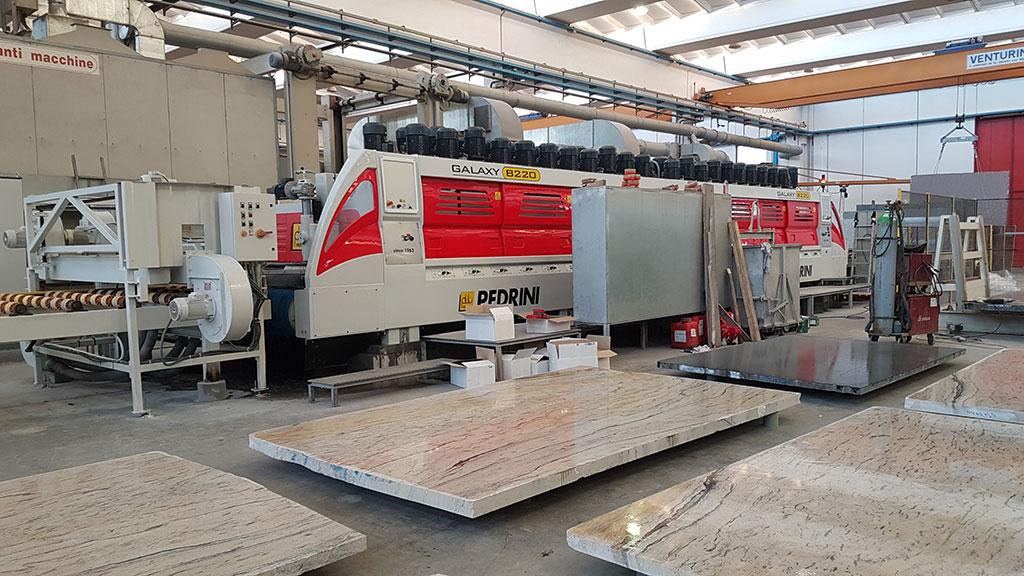

Marmi Rossi has got two Pedrini multiwire saws and one diamond wire saw in the saw mills.

Thanks to the company’s networking technology and remote control, the Pedrini multiwire saws are working continuously, obtaining always the best quality.

The diamond wire saw is used upon request to cut sections or to align and adjust a block before it is cut into slabs. A block can be divided or cut in several parts before being cut into slabs, in order to check the colour, quality and defectiveness of a block.

The ‘standard thickness size‘ of slabs is 2 or 3 cm, but upon request, other sizes or customised sizes can be produced.

PROCESSING / SURFACE FINISHING

Besides the multi wire saws, that are cutting continually blocks into slabs, our company has got other machines that polish and hone raw slabs to produce different surface finishing for our customers.

Each slab is calibrated after the cutting to obtain a homogenous thickness, then, depending on the type of material and the customer’s request, the surface is finished to emphasise the beautiful features of the slab.

The most sought after surface finishing are polished, honed, satined and flamed surfaces, but there are several other solutions, either the above mentioned are combined with each other or new techniques are used, e.g. water jet. If you like to learn more about surface finishing, come visit us.

Mostly we choose the finishing for a slab’s surface, depending on the material type and the purpose, because some finishing is not suited for exterior, but only for interior design.

A polished surface should only be used in interior spaces, whereas a honed surface and similar alternatives are suited for outdoor areas. Then again, there is no reason why you should not use flamed surfaces for interior design, particularly if in contrast to other finished surfaces.

SLAB WAREHOUSE

At the end of the production phase, all slabs are stored in our four different warehouses in Cavaion Veronese.

Every day, our customers have at their disposal more than 20.000 slabs.

The slabs are stored according to typology (marble, granite or quartzite), origin and colour.

Each slab in our warehouse is labelled with a specific code which enables us to check the quantity and availability of every material in real time.

Thanks to this codification, all slabs are registered in our computers and can be checked on our website on warehouse online.

On appointment and during the exhibition days of Marmomacc, all materials can be daily visited in our warehouses.